Landfills

Bharti FerroSorp® S

Pelletised hydrogen sulfide filter media for external desulfurization of landfill gas

Landfill gas contains many pollutants. Among them is H2S which is known to be extremely toxic, highly corrosive, and foul-smelling. Maximum concentration thresholds for H2S vary from site-to-site and are limited either for technical reasons (to protect downstream equipment and machinery such as CHP’s, turbines, gas-upgrading equipment, etc.) and/or for regulatory reasons mandated by government agencies (i.e. air- quality standards, SO2 emissions, etc.).

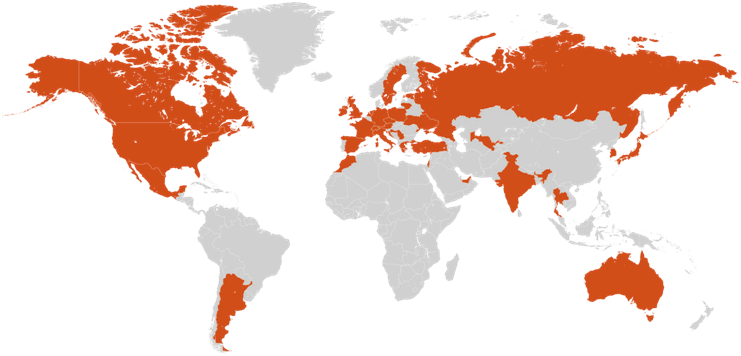

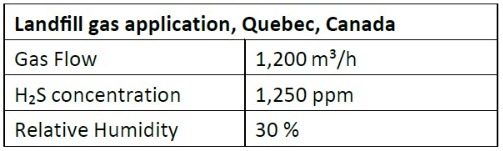

To consistently achieve technical and regulatory compliance, a robust, economical and effective solution, such as FerroSorp® S – a high quality product Made in Germany – is required. For over 20 years FerroSorp® S has proven itself to be the best product for the job, even under some of the harshest, most-challenging gas conditions. The result is, that each year more and more sites around the globe opt for using FerroSorp® S as their solution to the H2S problem.

The process

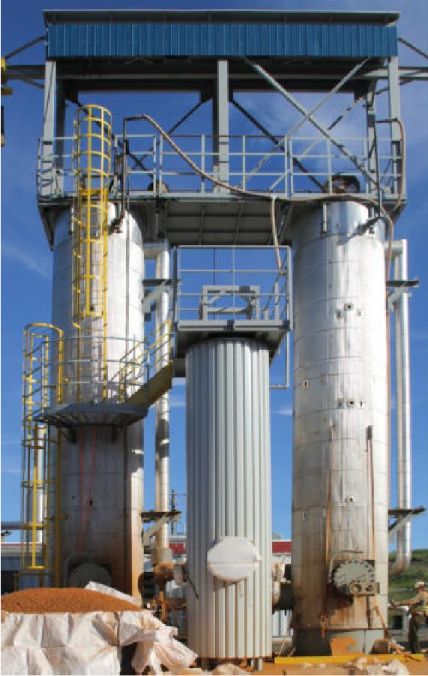

Gas containing H2S is passed through a filter vessel filled with FerroSorp® S media pellets. Two chemical reactions occur: First, H2S and iron hydroxide react to form solid iron sulphide. Second – either simultaneously or in a parallel vessel – oxygen converts the pellets back into iron hydroxide in a process called regeneration. Elemental sulphur is formed and accumulates within the pores of the media pellets, which results in high loading rates, long media lifecycles, and minimised clumping.

Our Advantages

- Used and tested for more than 20 years

- High purification performance

- High economic value

- High loading rates for H2S

- Minimised losses in pressure drop due to optimized pellet shape

- Achieves 0 ppm H2S at the outlet

You can choose from our broad selection:

SOME OF OUR ESTEEMED CUSTOMERS